Low-carbon hydrogen: What are the relevant medium-term uses in a decarbonized world?

Summary of the study

Context: low-carbon hydrogen raises hopes to respond to the climate emergency

Respecting the Paris Agreement means "avoiding the unmanageable" by limiting the worsening of the climate change that is already underway. To do this, we need a strong and quick reduction of global greenhouse gas emissions, that must come with a sharp decrease in the consumption of fossil fuels. To achieve this, a small molecule is giving rise to a lot of hope: hydrogen. If not carbon intensive, it is an answer to dealing without fossil fuels for certain activities and managing the energy transition, while strengthening our independence.

In this context, Carbone 4 has conducted a prospective study on the potential of low-carbon hydrogen according to the different consumption segments and considering other decarbonizing options, in order to enlighten the public debate on the most efficient uses of hydrogen to respond to the climate emergency.

Hydrogen today: mainly consumed in industry, it is mainly produced from fossil sources

Most of the hydrogen is currently used as a feedstock in the industrial sector. Worldwide, it is currently consumed at about 115 MtH2 per year, with a slight increase in recent years. 70% of the consumption is distributed among refining, and methanol and ammonia production.

On the one hand, hydrogen is largely (approx. 40%) a co-product of activity (e.g. in coke oven gases). On the other hand, the "dedicated production" (approx. 60%), hydrogen is today almost entirely produced from fossil resources: coal gasification and especially steam reforming of natural gas represented more than 99% of dedicated hydrogen production in 2018. Hydrogen thus currently has a high average carbon footprint[1]: 15 kgCO2e / kgH2 for dedicated hydrogen production, making it one of the energy carriers with the highest carbon footprint.

Decarbonizing hydrogen production is possible through electrolysis, but will potentially remain more expensive than fossil production

However, there are processes allowing the production of a less carbon intensive hydrogen, even though these processes are usually more expensive. The main one, electrolysis, consists of separating the dihydrogen molecule from the oxygen atom that makes up the water molecule, with a high electricity consumption.

Electrolysis enables the production of low-carbon hydrogen if the electricity itself is low-carbon. Thus, electricity with a carbon content lower than 60 gCO2e / kWh is required to produce low-carbon hydrogen as we define it in this study. We have retained the carbon footprint threshold according to the European Taxonomy, i.e. 3 kgCO2e / kgH2.

In terms of cost, based on energy prices before the Ukraine war, low-carbon hydrogen by electrolysis would not be competitive with hydrogen from fossil sources. According to our prospective modelling, the cost of production by electrolysis could be between 3 and 4 € per kg of hydrogen by 2030, compared to about 1 € for production from fossil sources. These analyses are nevertheless very sensitive to the hypotheses concerning the price of the different energies. As a matter of fact, the production cost of fossil hydrogen from natural gas, whose price has recently exceeded €100/MWh, would oscillate around €5 per kg of hydrogen. It is the same dynamic with the current market prices of electricity for electrolysis.

Study approach: evaluate the potential of low-carbon hydrogen by 2030 for 11 uses, especially through a cross-analysis between these uses

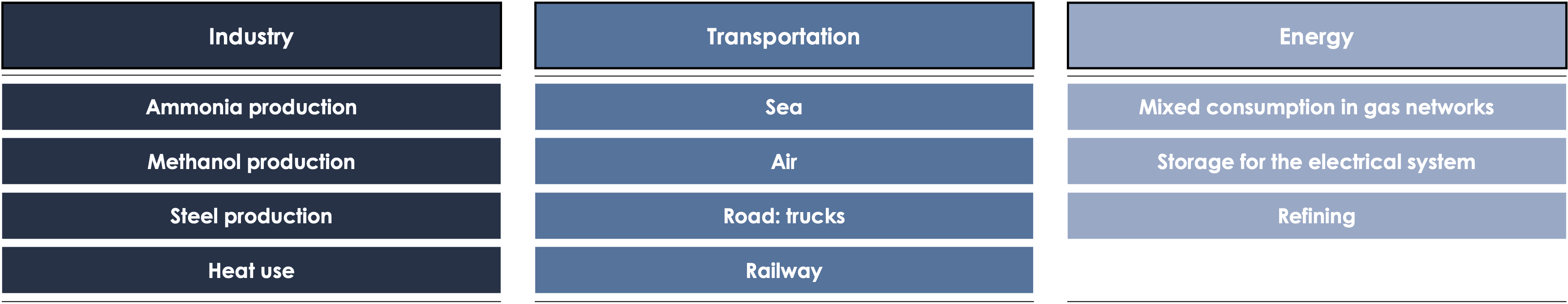

We considered a set of 11 possible uses of hydrogen, distributed within 3 sectors, with a temporal focus on low-carbon hydrogen consumption by 2030.

The study of a potential low-carbon hydrogen use starts by assessing its relevance within the use, based on its unitary decarbonization potential[2] and its comparative advantages or disadvantages compared to other decarbonizating options. Then, we have determined potential volumes of low-carbon hydrogen for the different uses, notably, when possible, using sector decarbonization targets to deduct these volumes in a normative way.

The great interest of the study lies in the last step, which is to proceed to an inter-use or inter-sector analysis, in order to result in an order of merit for the use of low-carbon hydrogen among the different uses studied. This analysis is based on the decarbonizing intensity of hydrogen: this metric, expressed in tCO2e / tH2, translates the reduction of the carbon footprint (expressed in tCO2e) of a use that low-carbon hydrogen enables, for one unit of hydrogen (expressed in tH2).

Lessons learned from the study: low-carbon hydrogen should be prioritized for ammonia and methanol production, direct reduced iron for steel production and e-LNG and e-methanol for the maritime sector

For the current uses of hydrogen, which are the production of ammonia, mainly for manufacturing fertilizers, and the production of methanol, it is necessary and a priority to substitute fossil hydrogen with low-carbon hydrogen in order to decarbonize these uses for which few other solutions exist.

The steel industry (for the direct reduction of iron ore) and the maritime sector (for the production of e-LNG and e-methanol) will necessarily need low-carbon hydrogen in the medium term to follow their 2°C trajectory. For both sectors, hydrogen is essential and complementary to other solutions: the development of recycling and carbon capture for steel, and bioenergy for maritime. For marine fuels, e-LNG can be easily used in existing or new LNG ships to reduce greenhouse gas emissions and save natural gas.

The use of hydrogen as a flexibility brick for electrical systems will probably be unavoidable, in the medium term and especially in the long term, to accompany the development of variable electricity production means, such as wind power and photovoltaic pannels.

The aviation sector will also need access to low-carbon hydrogen for synthetic fuels, again as a complement to bioenergy, but in the longer term: the potential volumes in 2030 are almost zero. Hydrogen for direct use in aviation will not see the light of day before 2035 because the technologies are not mature enough.

For refineries, the relevance of low-carbon hydrogen is uncertain: they could benefit from the use of low-carbon hydrogen now, even if the decrease in emissions is proportionally low. It is likely that carbon capture is a pathway that better fits the sector's needs, even if its decarbonization cannot be entirely based on this solution (limited accessibility to deep geological storage). Finally, an allocation of hydrogen in this sector must be made taking into account the necessary decrease in the volumes of activity in the sector over the coming decades.

For railways and trucks, the use of hydrogen is relevant but in limited quantities for certain very specific situations (strong need for autonomy for example, or in the form of hybridization between batteries and hydrogen within the same vehicle). These sectors will be decarbonized through electrification. Although the unitary decarbonization potential of hydrogen is high in these sectors, the decarbonization intensity[3] of hydrogen is low. It is therefore preferable to use low-carbon hydrogen for other uses.

For the production of ammonia as a synthetic fuel for the maritime sector, the allocation of low-carbon hydrogen is not relevant: there are still uncertainties about the technology on the one hand (incomplete combustion leading to nitrous oxide emissions and toxic ammonia leaks) and above all, as the decarbonizing intensity is lower than for other fuels, it is preferable to use low-carbon hydrogen for other uses, whether for the production of the other synthetic fuels studied within the maritime sector, or else for other sectors.

Hydrogen consumption in gas networks and hydrogen injection in blast furnaces are not relevant applications to be developed for hydrogen, because they do not generate enough emission reductions in their sectors. The decarbonizing intensity of these uses is also low, in absolute terms for hydrogen consumption in gas networks, or compared to the direct reduction of iron ore in the case of the steel industry.